So let us help you with this brass fittings guide, as we have mentioned everything you need to know about brass plumbing fittings, i.e., their importance, their material composition, and how they compare with other materials like stainless steel.

- Home

- Product

- Brass Fittings Parts

- Brass Sensor Parts

- Brass Turned Parts

- Brass Forging Parts

- Valve Parts and accessories

- Brass Valve Manufacturers

- Brass Pipe Fittings

- Brass Gate Valve

- Brass Float Valve

- Brass Housing Sensor Parts

- Brass Precision Sensor Pipe

- Brass Temperature Sensor Parts

- Brass Flow Sensors

- Brass Pressure Sensor

- Brass Auto Parts

- Brass Switch Parts

- Brass Solenoid Valve

- Brass Shut Off Valve

- Brass Manifold

- Brass Rotary Unions

- Brass Screw Joint

- Industrial Brass Ball Valves

- Brass Stem Nut

- Brass Nut

- Brass Bonnet Packing Nut

- Brass Bearing

- Brass Bushing

- Brass Pneumatic Fittings

- Brass Hydraulic Fittings

- Brass Electrical Parts

- Machinery

- Services

- Quality

- About Us

- Blog

- Contact Us

Blog

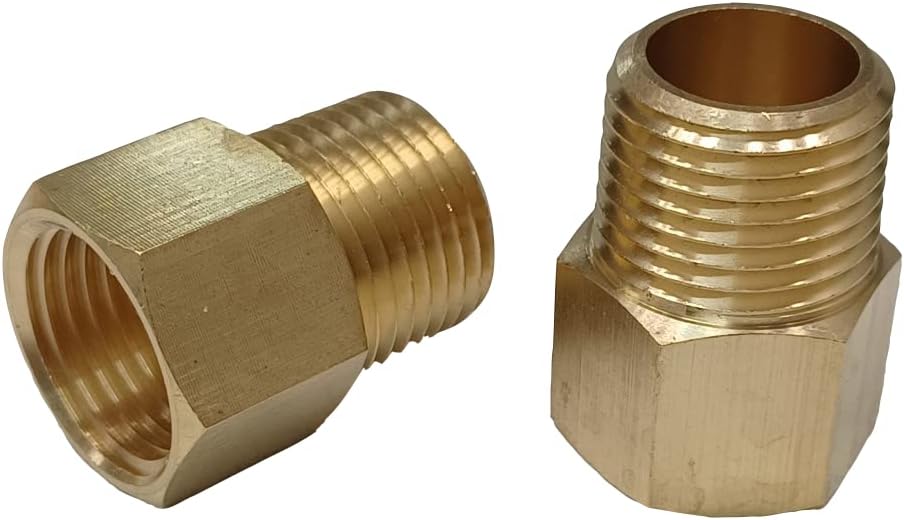

Brass pipes are used to join two or more sections of pipe in plumbing and engineering. You will often find the brass tubing welded to the end of the pipe in order to be connected with another component, or perhaps it is secured rigidly on a short length of pipe.

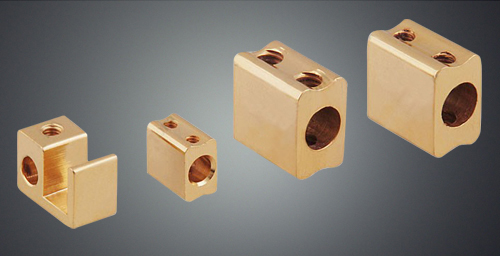

We manufacture and supply brass sensor parts made of high-quality materials and advanced technology. These components are used as housings for water level and telemetry devices. These products are designed to withstand chemical and alkaline attacks and extreme environments.

It is mainly used in the manufacturing industry and has obvious advantages, Brass Turned Parts Manufacturer.

We specialize in high-quality brass forgings for the specific needs of our customers. Our components are designed for high performance and quality in numerous fields, allowing your systems to remain smoothly operating.

When it comes to plumbing, choosing long lasting and dependable materials is important for making sure a protracted-lasting and green system.

Today, dependability of electrical and electronic contacts cannot be over-emphasized in the industrial world, domestic use or even in data communication.

In the manufacturing industry, choosing the right process and materials influences the final quality, strength, and execution.

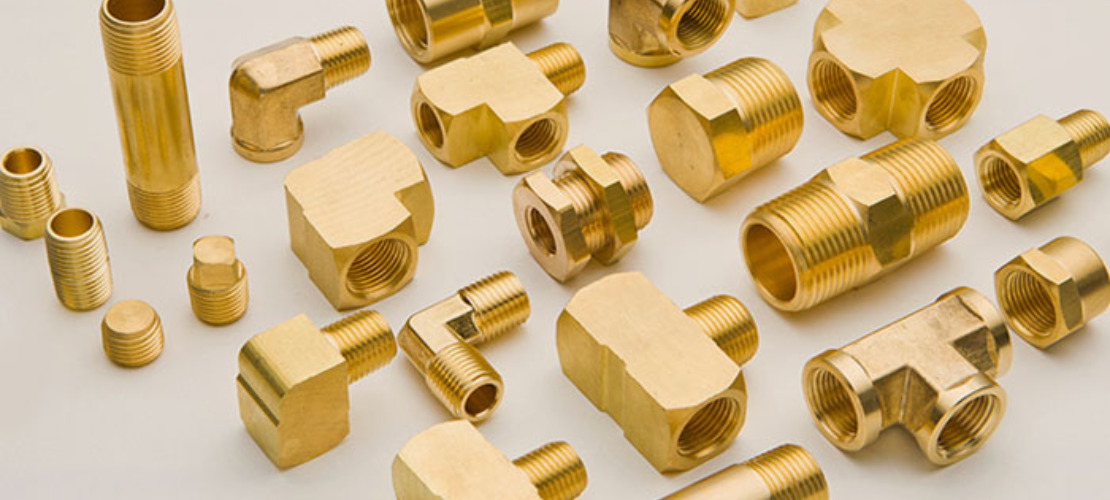

Brass fittings are well known for their durabilityand beauty. Itis broadly utilized in different undertakings like plumbing.

Business applications require unique and durable additives to ensure seamless operation and long-lasting overall performance. Sensors, being essential components in tracking and controlling business procedures, call for exceptional substances for the best capability.

Forged brass has, for a long while, been an establishment material for different industries as a result of its extraordinary strength, robustness, and disintegration resistance.

Plumbing systems are a crucial piece of any building, solid areas that require proficient materials to guarantee life length and ideal execution.

Bathrooms now symbolise aesthetics with utility. Brass pipe fittings manufacturers in India are thus likely to be in every homeowner's mind and, in turn, in each interior designer's mind, with examples of elegance and durability.

Brass fittings are also popular for plumbing and construction projects due to their extreme durability and elegant appearance. However, even the best material has its limitations.

It is quite logical that plumbing for a house may be done using any material, nevertheless, there are basic differences between them that influence plumbing function and safety significantly.

Brass also known as CuZn, exhibits high durability, high endurance to corrosion, high endurance to wear and tear, and has an appealing golden color.

This question flows strongly when industries are assessing the most effective procedural methods of producing brass parts.

Brass fitting is widely used in almost all fields possibly because besides being very strong they also do not rust easily.

Brass fittings are one of the important parts of various industrial applications as they act as a connector to carry various chemicals due to their extraordinary characteristics including corrosion resistance, high strength, and durability.

With regards to the production of metallic additives, popular strategies are Brass Forging Over Casting Parts. Both tactics have their very own benefits.

Brass gate valves are extensively utilized in plumbing, business, and commercial programs. They provide extraordinary management over fluid that goes together with the glide and are diagnosed for his or her sturdiness and reliability.

Modern-day copper and zinc are mixed to create brass, an alloy recognized for its superb machinability, resistance to corrosion, and durability.

Brass, an alloy of copper and zinc, has been a cornerstone of plumbing for many years. It offers several blessings over plastic or special steel valves.

Let’s understand brass parts. If you’ve ever taken apart a faucet, fiddled with a car engine, or marvelled at the tiny parts inside a medical device, chances are you’ve encountered brass-turned parts.

Brass-turned components are resistant to corrosion and are made from a precision process, intricately crafted with durable alloy. This process is known as turning, based on a method lathe.

Picking between brass and copper fittings is not just about grabbing a metal off the shelf. It is about understanding what each brings to the table.

In the domain of brassworking, two essential methods are utilized to shape brass into wanted parts: forging and casting.

Technological advancement proceeds with speeds that we have not witnessed before. The smooth operation of modern technology depends on precision components because technology uses them in critical applications.

As per MRFR analysis, the Pipe Fittings Market Size was estimated at 16.75(USD Billion) in 2024. Any residential, commercial, or industrial establishment needs a dependable plumbing system as its base.

Brass serves as an important material throughout all sectors related to manufacturing and construction and in the field of brass industries in India.

Leakages in piping systems can result in severe material loss and, alongside that, in water wastage, destruction of the building structure, and, in addition, contributing to higher repair costs.

India's industrial sector has been through an amazing increase at the beginning of the last several years thanks to manufacturing, engineering, and technology improvements.

Brass is one of the most commonly used metals in the industry because of its durable mechanical properties, corrosion resistance, and also proper appearance.

Brass float valves are the primary agents to manage the water levels in tanks and reservoirs effectively.

In 2025, global trade faces challenges once more. This time, the brass industry finds itself under strain.

The popularity of plastic pipes alongside brass compression fittings on plastic pipes continues to increase in Indian residential and commercial properties because they deliver affordability alongside durability.

In India, where plumbing systems have a mix of old and new installations, learning how to join a copper pipe to a brass fitting is a handy DIY skill to have.

When you think about plumbing, gas distribution, and many industrial jobs, threaded brass pipe fittings always come to mind as a solid pick. People know these fittings to last long and fight off rust.

When we refer to brass electrical parts manufacturers in jamnagar, India is the hub of quality and precision.

Brass is one of the most popular and versatile metal alloys used in modern manufacturing. Composed primarily of copper and zinc, brass offers an excellent combination of durability, corrosion resistance, machinability, and aesthetic value.

Brass is a top choice for plumbing due to its ability to handle both hot and cold water.

If you're working in manufacturing, construction, plumbing, or design, choosing the right metal can make or break your project.

It is applied to make one of a kind elements like pipe fittings, valves, electrical elements, and greater.

Interfacing copper channels to strung brass fittings is a common plumbing assignment.It is easy to string brass pipe fittings since they do not rust.

In the rapidly evolving field of sensor technology, especially in the context of sensor materials, the choice of materials is crucial in determining sensor functionality, stability, and reliability.

Brass, an alloy primarily composed of copper and zinc, has been a cornerstone material in industrial applications for centuries and has a perfect combination of strength, corrosion resistance, and machinability.

In industrial manufacturing, accuracy, longevity, and cost are driving success. Brass turned parts, made through high-speed, computer-controlled lathes, are characterized by their exact size and excellent performance under difficult conditions.

The most trustworthy and beneficial manufacturing method for producing high-quality parts is brass forging. Brass, an alloy of copper and zinc, is used due to its good mechanical properties and workability and has been used for centuries.

So what to choose, brass pneumatic fittings vs. plastic, depends on the specific application and needs. Brass provides strength, resistance to erosion, and good high- pressure operations and surroundings with corrosive fluids.

With regard to the new plumbing systems, the fittings may matter a lot with respect to durability, efficiency and subsequent costs.

On the topic of plumbing, materials involved are the determinants of success or failure to come up with a durable, efficient, and cost-effective plumbing in the long run.

In the busy world of industrial engineering and manufacturing, selecting the right components greatly impacts the performance and durability of many finished products.

When choosing nuts in the world of fasteners, making the right nut choice is an important factor that will affect the success of your project over the long term.