Blog Details

Why Electrical Brass Parts Are Essential for Reliable Connectivity

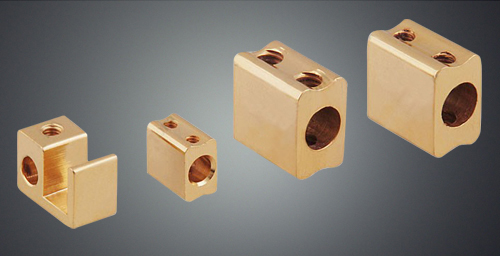

Today, dependability of electrical and electronic contacts cannot be over-emphasized in the industrial world, domestic use or even in data communication. Standing at the centre of these connections are Electrical brass parts and these are very reliable and long lasting. Brass Electrical Parts can be foreseen as an important element of different industries caused by their conductivity, sturdiness, and resistance against corrosion what ensures stable connections and constant electric current.

The Importance of Electrical Brass Parts with Regard to Connection

Electrical brass parts prove extremely useful in the proper functioning of circuits, systems, and networks. These parts are designed for high current capabilities, to withstand environmental conditions and to be accurately incorporated into intricate circuits, thus minimizing connection breakages.

Brass is an ideal material for components that are the building blocks of electrical connectivity including connectors, terminals, switches, and fasteners. The ever increasing use of the brake electrical parts in various sectors is a clear indication of the role and significance of parts made from this material.

Why is Brass Suitable for Electrical Items?

Brass is an alloy mainly containing copper and zinc and characterized by strength, ductility, and high resistance to corrosion. These characteristics make it right for electrical components that require to operate under difficult situations without compromising on their efficiency. Here are some reasons why brass is the preferred material:

- High Conductivity: Brass is one of the best conductors of electricity and therefore used for making parts where easy flow of current is required. Brass electrical parts contribute to low energy consumption and stabilizes itself for consistent performance especially for applications requiring efficient transfer of power.

- Corrosion Resistance: Another common problem is that electrical systems are usually located in environments where they can be exposed to moisture and heat that in turn leads to corrosion of the metal parts of electrical systems. Brass is not affected by corrosion and these conditions do not affect the structure of the material and connection can be maintained over long periods.

- Durability and Strength: Electrical brass parts are strong because brass is strong and can also take mechanical loads. For this reason, they are ideal for applications where a component will undergo frequent usage, such as auto and industrial uses.

- Ease of Fabrication: Brass is fairly malleable and it is not a difficult metal to either cast or machine; this makes it easy for manufacturers who need to make parts to precise specifications to use. It therefore enables making complex and well-tailored brass electrical parts in fulfilling connectivity demands.

Uses of Brass Electrical Parts

Electrical brass parts are found in a wide array of industries and applications, including:

- Automotive: Brass Electrical Parts are also applied in automobile electric systems, such as battery posts, switches, and connectors, because it possesses excellent performance at a high and low temperature as well as under different circumstances.

- Telecommunications: Due to the need of a secure data and signal transmission, brass electrical parts are used in connectors and adaptors to provide reliable and lasting connections.

- Electronics: When it comes to circuit boards right up to small wiring installations for consumer electronics, brass components ensure that the electrical connection is stable and hence the reliability of these devices is supported.

- Power Distribution: Brass products are widely used in the power distribution industry because they are incorporated in connectors, terminals and fittings for safe distribution of high voltage electric current.

Brass electrical parts and why they are used

This aspect shows that different types of Brass Electrical Parts are capable of fulfilling different connectivity requirements in the field. Here’s a closer look at some key types and their unique roles:

- Brass Connectors: Heaters are used in cases when a permanent splice is not necessary, and one is required to quickly join or disconnect the circuit while having an option to replace the connection easily. Brass connectors are quite suitable in that they are both steady and anti-corrosive so as to allow the current to flow smoothly.

- Brass Terminals: Applicable to fasten wires to electrical appliances, brass terminals are important in applications where wires may need to be connected or disconnected frequently. Due to the factor that these types of lamps are long lasting and easy to used and installed they are widely used in the industrial and commercial sectors.

- Brass Switch Components: Switches have brass parts integrated in their design in as they enable effective conduction and are durable. These components guarantee smooth continuity and a minimal likelihood of creating transient short circuits in conditions with high electrical load.

- Brass Fasteners and Screws: Common in circuit’s boards, junctions, and electrical enclosures brass fasteners guarantee strong connection to metallic surfaces in electrical assemblage. They furnish the needed strength and rigidity for structures without the possibility of rusting away or losing its structural characteristics.

Why Use Brass Electrical Parts When There Are Other Materials Available On The Marketplace?

There are a number of materials which can be used for Electrical brass parts and among them brass is preferred for some reasons. Such options as aluminum, copper, and stainless steel also have some advantages; however, each of them has its drawback, while brass has the highest conductivity, relatively high durability, and reasonable price. Here’s why electrical brass parts are often the preferred choice:

- Cost-Effective: Brass is basically cheaper than copper, but has comparable conductivity and performance than copper. It also makes it inexpensive particularly for large scale operations or large number of volumes of the product to be produced.

- Sustainable and Recyclable: Brass, in its totality, can be recycled which makes it a environmentally friendly material to be used in manufacturing. The recycled brass has some properties of the original material that is advantageous for companies that strive to be environmentally friendly.

- Low Maintenance: However, unlike other metals which have to be treated often to check on the corrosion, brass electrical parts are relatively easy to maintain and continue to offer optimum performance even when only a little attention has been devoted to it. This makes them appropriate for use in applications where components have to function under different parts of the curve.

Future Trends in Electrical Brass Parts

As more and more connectivity solutions are required in smart city applications, electric vehicles, and renewable energy, brass electrical parts will remain necessary. New developments in the brass alloy compositions and manufacturing techniques are anticipated to improve the strength and electrical conductivity of all these components even further, promising better improvements in high-frequency electronics and precision engineering.

Conclusion

Electrical brass parts are the fundamental of standard connections of different areas of functioning to guarantee stability, longevity, and affordability. In automotive, telecommunications or power distribution systems, Brass Electrical parts ensure vital connections that enable the functionality of everyday life. Due to its high conductivity, the ability to resist corrosion and high strength, brass is a preferred material since it provides reliable connection in industries.

Read More: Top Benefits of Using Brass Water Pipe Fittings for Your Plumbing System