Blog Details

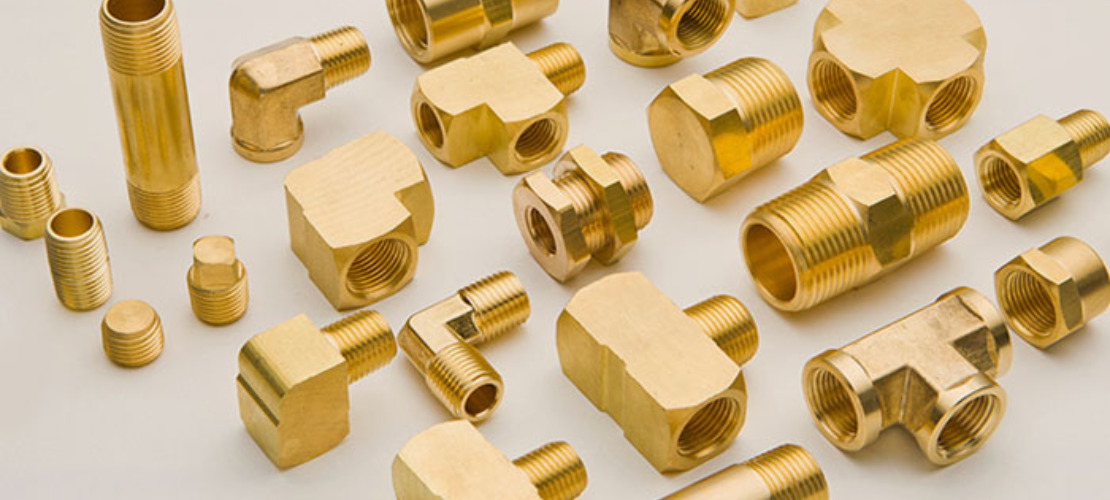

Brass Fitting Parts For Industrial Use

Introduction: of Brass Fitting Parts

So let us help you with this brass fittings guide, as we have mentioned everything you need to know about brass plumbing fittings, i.e., their importance, their material composition, and how they compare with other materials like stainless steel.

In this section, we are going to find out what kind of brass fitting parts types are available in the market and how they match with various pressure ranges for building a hydraulic line and its quality standards.

Brass Pipes—brass pipes refers to the special connections of some parts, and it is a connection made of brass, i.e., an alloy of copper [Cu] and zinc [Zn]. This component is crucial in joining pipes in numerous systems, such as plumbing, heating, and hydraulic systems.

How to Choose Brass Fitting

Understand the Program

Before you go through the selection of which would be more useful or practical to buy, it's important to learn the requirements of this app. Are you resistant to high pressure or higher temperatures? Understanding these factors can help you make a choice.

Material Quality is Important

Different types of brass exhibit different strengths, corrosion resistance, and machinability. Ensure the correct quality for your application. For example, lead-free copper is ideal for potable water systems.

Check Quality Standards

Make sure brass fitting parts meet recognized industry standards such as ASTM, ISO, or other certifications. The products are therefore rigorously tested to meet specific quality and safety standards.

Composition Types

There are many different types of brass hose products, such as compression, shell, and spiral. Each type has a specific purpose and is suitable for a specific use. You can choose the type you want.

Compatibility

Ensure that the type of material used for the accessory is appropriate—whether it be brass, plastic, or steel. Misalignment can cause leaks and system failures.

Budgetary Constraints

Yes, quality is important, but you should take care to save your wallet. Brass pipe fittings come in various affordable prices, and you can proudly say none of them will break.

Benefits of Brass Fitting Parts:

There are many benefits to using brass fittings in specific applications, including:

1.Physical Benefits

- Corrosion Resistance: Water, acids, and alkalis will not harm this material.

- High temperature resistance: Brass can work under high temperatures of 500 °C.

- Durability and strength: Industrial brass fittings provide high mechanical strength and wear resistance.

- Electrical Conductivity: Brass allows the passage of electrical current from one point to another.

- Thermal Conductivity: Brass is a good conductive material.

2.Performance Benefits

- Leak-resistant: Brass fittings reduce leakage and maintain a secure connection.

- Low maintenance: Brass brackets require minimal maintenance and cleaning.

- High pressure resistance: brass products can withstand high pressure (up to 1000 bar).

- Compact design: Brass appliances allow you to save space.

3.Industry-Specific Benefits

- Marine: industrial brass fittings are resistant to seawater corrosion.

- Aviation: brass equipment has high strength and light weight.

- Automotive: Brass fittings ensure reliable fuel and cooling systems.

- Industrial Automation: brass fittings allow precise water control.

- Medical: Brass fittings provide non-toxic, corrosion-resistant joints.

Application of Brass Fitting Parts

Exceptional flexibility, which means the material is more flexible than steel. Bronze is very soft, but still very strong.

wide variety, brass fittings manufacturers offer these in a variety of shapes and sizes and also come in numerous styles for hydraulic, pneumatic, and instrumentation applications.

Extremely durable, perfect for some food linen systems where chemicals, gases, and liquids are treated.

High temperature tolerance with good thermal conductivity. Brass products are more temperature-resistant than other materials. However, it should be noted that the allowable pressure ranges depend on the temperature as well as the type and size of the tube.

Let’s Explore Brass Components!

Brass components are all around you, from your bathroom accessories to orchestral instruments.

Types of brass components

There are many types of copper parts available to meet different needs. Here are some of the most common types.

- Pipe fittings: components are used to link pipes, valves, and gauges in plumbing lines.

- Electrical parts: sockets, terminals, and plugs used in electrical distribution.

- Door accessories: knobs, handles, and hinges.

- Furniture items: drawer pulls, handles, and decorative accents.

- Industrial components: gears, valves, and other parts used in machines.

- Brass gas parts: Brass components include fittings, valves, and plugs specifically designed for gas use.

Different Processes Involved in the Production of Brass Pipe Fittings

The creation of good-quality brass pipe fittings involves several processes. Below are the processes most involved in doing so:

- Evaporate Casting Model: As the name suggests, this casting process uses steam technology.

- Centrifugal Casting: This casting method is generally used for the development of thin walled cylinders.

- Continuous Casting: Molten metal allows to reach the final finish from a liquid state in this casting process. The continuous process is called continuous casting.

- Die Casting: This is another metal casting. During this process, the metals are strongly melted.

Conclusion

This guide will give you valuable information about brass fitting parts. Brass fittings are very soft, durable, and even more resistant to corrosion at room temperature. Zinc and copper are the two primary ingredients in the composition of copper alloys.

Read More: The Ultimate Guide to Brass Pipe Fittings: Types, Uses, and Benefits